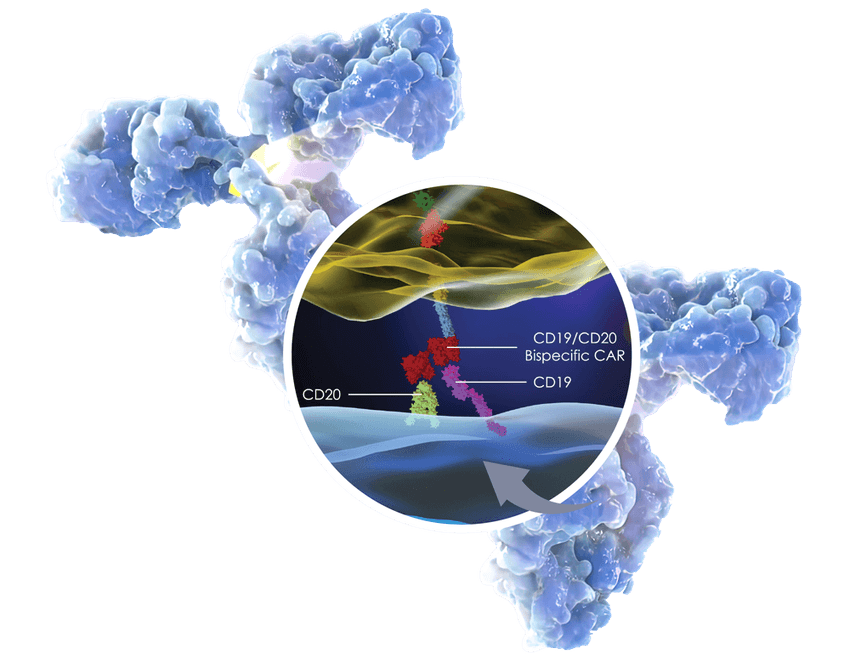

Capable of engaging two epitopes or antigens simultaneously, bispecific antibodies (bsAbs) are synthetic proteins that scientists engineer by combining antigen-targeting domains of two monoclonal antibodies (mAbs).1 Their dual-binding properties make these molecules more precisely targeted than conventional mAbs, and thus better suited for therapeutic applications. As of July 2025, regulatory agencies globally have approved 20 bsAbs, including catumaxomab, blinatumomab, and zenocutuzumab, for the treatment of various cancers, inflammatory disorders, ocular diseases, and hematologic conditions.1

Biointron offers expert bsAb manufacturing, rapidly delivering customized bsAbs while ensuring rigorous quality control.

biointron

Although bsAb drugs are growing in popularity, scientists face several challenges when manufacturing these complex proteins. Co-expression of the selected heavy chains (HCs) and light chains (LCs) often results in mispaired molecules, including non-functional antibodies with properties similar to the intended bsAb.2 Researchers may also encounter unwanted byproducts such as antibody fragments and aggregates during production. Structurally complex antibodies are especially difficult to manufacture, and the wide range of available formats complicates candidate selection. Consequently, optimizing HC and LC expression, selecting suitable formats, and removing impurities are critical steps in bsAb manufacturing.

Researchers can address these challenges by leveraging the advanced expertise of companies such as Biointron and their bsAb production service. With 13 years in the antibody expression industry, Biointron generates over 100,000 custom bsAbs annually in more than 260 formats. The company employs rigorous purification and quality control methods to effectively detect and remove impurities, such as aggregates, mispaired species, and fragments. Additionally, their short manufacturing timeline allows them to deliver purified bsAbs within two to three weeks of receiving the mAb sequences. By streamlining bsAb production, services like Biointron’s help accelerate research and therapeutic development.

Learn more about this fast, scalable bsAb manufacturing service.

- Labrijn AF, et al. Nat Rev Drug Discov. 2019;18(8):585-608.

- Chen SW, Zhang W. Antib Ther. 2021;4(2):73-88.