Courtesy of Vicki Colvin

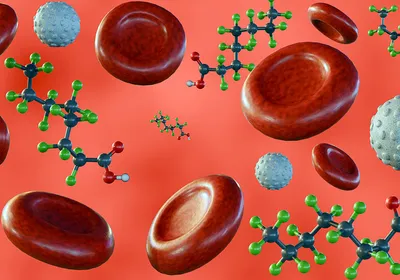

The cytotoxicity of three fullerene derivatives in cell culture (human dermal fibroblasts, 48-hour exposures). As the derivatization of the fullerene surface changes from a sparingly soluble version (black) to a fully hydroxylated material (blue), the dose that kills half the cells changes over many orders of magnitude. This result highlights the importance of surface coatings and derivatizations to biological activity.

When materials and devices are fabricated with tiny dimensions, their properties and applications expand enormously. Small size, which for nanotechnology means less than 100 nm, confers on devices and materials enhanced flexibility and improved performance. We've begun exploiting such properties in a multitude of emerging areas ranging from computing to translational medicine. Yet, just as the promise of nanotechnology becomes more defined, skeptics raise questions about the unforeseen risks this new technology may present for the environment and our health.12

For once, these concerns are not ...