Two years ago, the first employees of Tengion walked into a 2,800 square meter warehouse in southeastern Pennsylvania that was full to the brim with office furniture, rising up to a 12-meter ceiling, and said: We'll take it. They cleared everything out and started to fill the empty space with rooms and equipment to automate something that had never been automated before: human bladders.

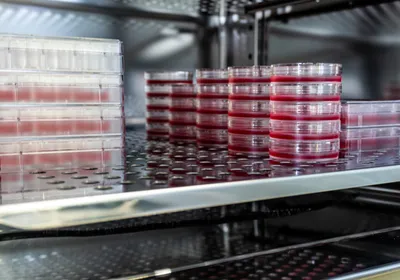

The facility reflects the uniqueness of the company's efforts. In mid-September, the building, part of an office park, is surrounded by piles of dirt and rocks, with a Caterpillar earthmover, frozen in mid-scoop. Standing before an architectural blueprint, Jason Krentz, a former Marine who now directs manufacturing at Tengion, points to the different areas. Sections in blue, green, and pink surround a center yellow square - the "cleanest" part of the facility, where workers delicately handle ...