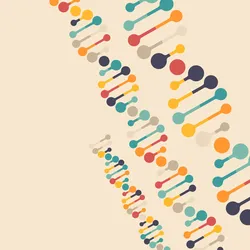

Courtesy of Zeptosens

Planar waveguide (PWG) technology (right) has the advantage over conventional epifluorescence excitation (left) for surface-confined assays in that only surface-bound fluorphores respond to the excitation source. Labels that are located more than about 400-nm from the surface do not fluoresce. Zeptosens uses PWG technology to enhance sensitivity of its protein arrays.

While not as ubiquitous as their DNA counterparts, pro tein arrays are starting to hold their own, appearing as the key technology in a growing number of published research papers and even starring in their own new textbook. And their potential to be major players in the proteomics field appears boundless. "The protein field is about 10 times the size of the DNA field, so ... I think we can probably expect the protein microarray field to be much larger than the DNA microarray field," says Mark Schena, visiting scholar at TeleChem International, ArrayIt Division, Sunnyvale, ...