Interlocking layers of Tissue-VelcroZHANG ET AL. SCI. ADV. 2015;1:e1500423

Interlocking layers of Tissue-VelcroZHANG ET AL. SCI. ADV. 2015;1:e1500423

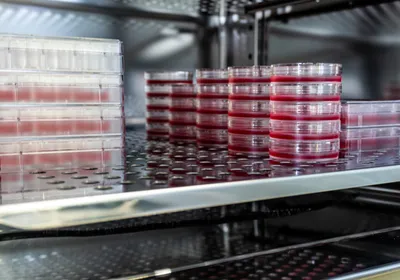

The technique: To rapidly assemble and disassemble engineered tissue in culture, researchers at the University of Toronto have designed a system of biocompatible scaffold sheets that, once covered in cells, can be layered together and pulled apart like Velcro. Announcing their technique in a Science Advances paper published today (August 28), the researchers describe the use of “Tissue-Velcro” to build 3D heart tissues that beat spontaneously and synchronously.

“The heart is made pretty much like layers of cells stacked on top of each other, so what this paper is [describing] . . . is these layers of scaffold that have heart cells and endothelial cells and that have a clever way of being linked together,” said Ali Khademhosseini of Harvard Medical School who develops biomaterials ...