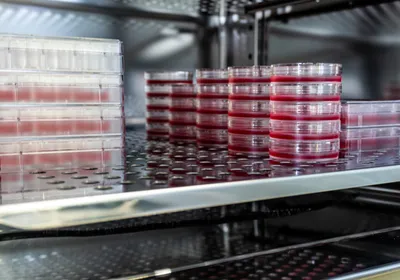

WIKIMEDIA, RAINIS VENTAIn 2008, a team led by Stanford University’s Christina Smolke, then at Caltech, showed in Nature Chemical Biology that engineered yeast (Saccharomyces cerevisiae) could produce benzylisoquinoline alkaloid (BIA) metabolites, including the alkaloids from which morphine is derived. Now, in a paper published today (August 24) in the same journal, Smolke’s team shows that S. cerevisiae engineering to express additional enzymes can be coaxed to synthesize naturally occurring opiates and semisynthetic opioids from BIA precursor molecules. The results represent a step toward engineered yeast–based biomanufacturing of morphine.

WIKIMEDIA, RAINIS VENTAIn 2008, a team led by Stanford University’s Christina Smolke, then at Caltech, showed in Nature Chemical Biology that engineered yeast (Saccharomyces cerevisiae) could produce benzylisoquinoline alkaloid (BIA) metabolites, including the alkaloids from which morphine is derived. Now, in a paper published today (August 24) in the same journal, Smolke’s team shows that S. cerevisiae engineering to express additional enzymes can be coaxed to synthesize naturally occurring opiates and semisynthetic opioids from BIA precursor molecules. The results represent a step toward engineered yeast–based biomanufacturing of morphine.

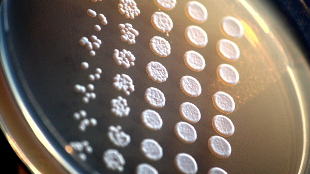

“The authors have demonstrated that it is possible to develop a technology platform in yeast that allows the transformation of [the opiate alkaloid] thebaine to a variety of opiate drugs by mixing and matching microbial and plant enzymes,” biochemist Neil Bruce from the University of York, U.K., told The Scientist in an e-mail. “This is elegant piece of synthetic biology . . . and demonstrates that it may ultimately be possibly to generate a [complete] morphinian biosynthetic pathway in yeast.”

Smolke and her colleagues have been working to reconstruct this pharmaceutically relevant pathway in yeast for nearly a decade. “When we started this project about 10 years ago, we were interested in plant natural product pathways [and] developing new ways to source these compounds because ...